Integration of VR and Visualization Tools to Foster the Factory Planning Process

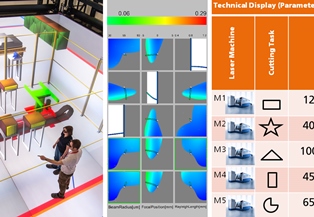

Recently, virtual reality (VR) and visualization have been increasingly employed to facilitate various tasks in factory planning processes. One major challenge in this context lies in the exchange of information between expert groups concerned with distinct planning tasks in order to make planners aware of inter-dependencies. For example, changes to the configuration of individual machines can have an effect on the overall production performance and vice versa. To this end, we developed VR- and visualization-based planning tools for two distinct planning tasks for which we present an integration concept that facilitates information exchange between these tools. The first application's goal is to facilitate layout planning by means of a CAVE system. The high degree of immersion offered by this system allows users to judge spatial relations in entire factories through cost-effective virtual walkthroughs. Additionally, information like material flow data can be visualized within the virtual environment to further assist planners to comprehensively evaluate the factory layout. Another application focuses on individual machines with the goal to help planners find ideal configurations by providing a visualization solution to explore the multi-dimensional parameter space of a single machine. This is made possible through the use of meta-models of the parameter space that are then visualized by means of the concept of Hyperslice. In this paper we present a concept that shows how these applications can be integrated into one comprehensive planning tool that allows for planning factories while considering factors of different planning levels at the same time. The concept is backed by Virtual Production Intelligence (VPI), which integrates data from different levels of factory processes, while including additional data sources and algorithms to provide further information to be used by the applications. In conclusion, we present an integration concept for VR- and visualization-based software tools that facilitates the communication of interdependencies between different factory planning tasks. As the first steps towards creating a comprehensive factory planning solution, we demonstrate the integration of the aforementioned two use-cases by applying VPI. Finally, we review the proposed concept by discussing its benefits and pointing out potential implementation pitfalls.